We specialise in providing quality Darwin concrete floor grinding, polishing and finishing. You can count on us to deliver outstanding results for your home, office, factory floor or any other premises.

Polished Concrete

Floor Grinding NT are also HTC Superfloor(TM) accredited. We provide a complete concept for polishing concrete. A premium polished concrete is a mechanically refined concrete floor. This method involves removing the surface paste and exposing the underlying stronger concrete. The extensiveness of the work involved depends on the exposed aggregate, the depth of grinding required and the kind of concrete that has been worked and finished by a concrete contractor.

To achieve a polished appearance, we begin with a rough grind and gradually grind up to a fine grade. Using quality diamond segments and special resin bond tools on the floor surface, we can transform a concrete floor to a beautiful surface. Between concrete grinding stages, concrete hardeners (densifiers) are used to increase durability and strengthen the concrete floor.

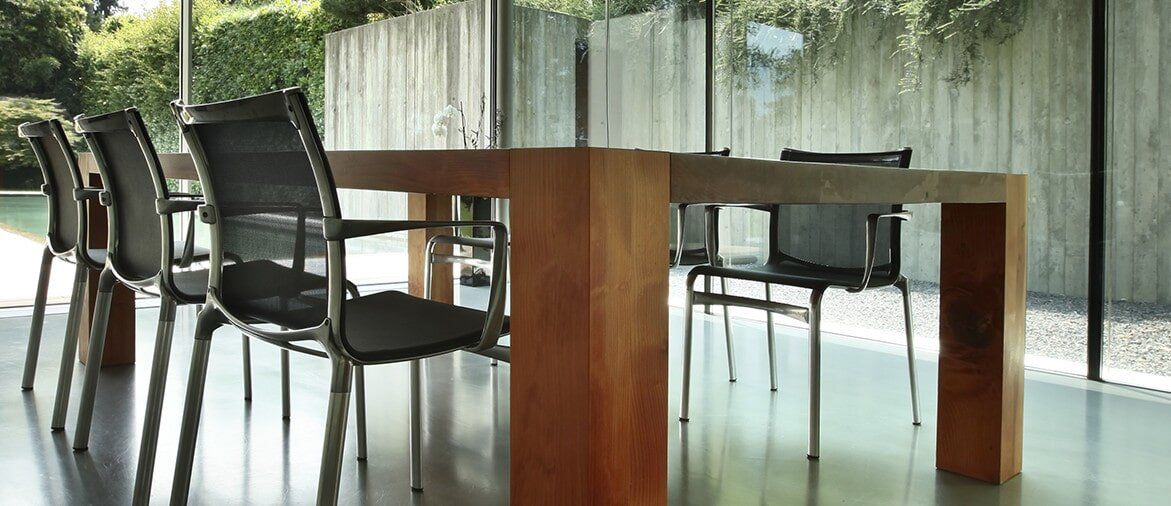

Once the finished appearance is achieved, a special concrete penetrating sealer is applied. It is important to keep in mind that the sealer is not a coating but simply a stain resistant sealer, which penetrates beneath the surface to enable cleaning and to stop a majority of contaminants from staining the concrete floor. The end result of this premium polished method will be a very smooth and durable surface, perfect both functionally and aesthetically.

A finished polished concrete floor will enhance the natural beauty of your home and also create a low-maintenance, durable floor.

Polished Concrete With A Topical Sealer

This is a concrete floor surface that has been mechanically ground back using diamond tools. Depending on the concrete floor surface presentation, usually two our more grinding process stages can be performed and then a topical sealer applied. Topical sealers refer to a type of coating which covers the surface of the concrete, providing a protective barrier. It is a layer of thin film sitting on top of the concrete. Both solvent and water-based sealers available.

Seamless Epoxy Floors

Our Darwin concrete floor experts can apply decorative epoxy coatings, acrylic flake systems and stone grip (river sand) systems. Epoxy coatings can incorporate acrylic flakes, with an extensive range of base colours and patterns to choose from.

Another system that can be used with epoxy is the stone grip system. This comprises a combination of micro flakes and river sand, which is primarily used where a non-slip floor is required. It also displays a beautiful colourful texture.

Concrete Floor Grinding Surfaces

Grinding all old & new concrete floors Floor preparation/stripping old finishes involve grinding and preparing the concrete floor. Removal of floor substrates, ceramic tile & vinyl adhesives, paint, glues, epoxy, self-levelling epoxy, putty and much more.

Grinding and Levelling

This process involves preparing the surface by grinding and removing any irregular spots or humps in the floor surface.

We Use Quality Concrete Finishes

These include:

- Topical coatings & impregnating sealers

- Water based sealers

- Seamless epoxy

- Densifiers

- Non-slip coatings

Floor Grinding Machines Used

Swedish company HTC are the leading manufacturer and supplier of floor grinding equipment. They have the largest range of floor grinding machines for floor preparation and floor polishing.

We use an extensive variety of HTC Machines. This includes HTC floor grinders, HTC edge grinders and HTC dust extractors. The machines we use range from heavy duty three-phase and single-phase grinding machines, through to handheld grinders.

The floor grinding units we use are among the latest and most advanced anywhere in the world. All our grinding machines use a dry grinding method. They are equipped with a heavy duty three-phase and single-phase dust extraction system to minimise dust within the surrounding areas. The systems we use are safer, cleaner and more environmentally efficient than other options.